GSORT

EXCELLENCE IN DENSIMETRIC SEPARATION

GSort

The requirements for separating materials with different densities are becoming ever more demanding. And whether it is the purity of the separated materials, the performance of the machine or compliance with environmental standards that guarantee a sustainable process – Mogensen has the right answer with its latest development: the GSort Densimetric Table.

The GSort utilizes a density separation process that operates on an inclined vibrating deck. As an upward air stream flows through the deck, it differentially affects the materials being sorted:

- Lower density materials move downward along the incline, floating above the deck without making contact.

- Higher density materials maintain contact with the vibrating deck and are carried upward by the motion.

The GSort is designed for easy and rapid customization of operational parameters, ensuring optimal alignment with the specific characteristics of the material being processed. Precision in separation is attained by fine-tuning the following settings:

- Air flow and its velocity distribution

- Positioning of the overflow flap

- Angle of the table tilt

- Frequency of the vibration

Once installed, the required air flow is set, followed by an internal mechanism efficiently adjusting the air flow distribution within the table. This process guarantees the GSort operates with the highest precision for your material separation needs.

The GSort can separate high-density materials up to 80 mm in size, depending on the specific density of the material. Its flexible configuration options allow it to process a wide range of materials. The production capacity for a given product mix is directly proportional to the density difference of the materials. For product mixtures with small density differences, pre-screening into fractions is recommended.

We work closely with our customers to select the appropriate GSort model for their application, ensuring a significant return on their investment.

Options:

The GSort’s exhaust air is treated by either cyclones or bag filter systems, effectively separating air from dust. The cleaned air is then extracted by a fan.

By integrating our vibration distributors, it is possible to operate up to four GSort units in parallel. In addition, our MSizer can process different fractions, which can then be sorted by the GSort or in conjunction with our MSort electro-optical classifiers, increasing the efficiency and versatility of the separation process.

- The GSort outperforms traditional sorting methods by up to 80%.

- This densimetric table can replace or complement wet gravity separators, improving water management and reducing energy costs. Its design also reduces installation, dismantling and transport costs.

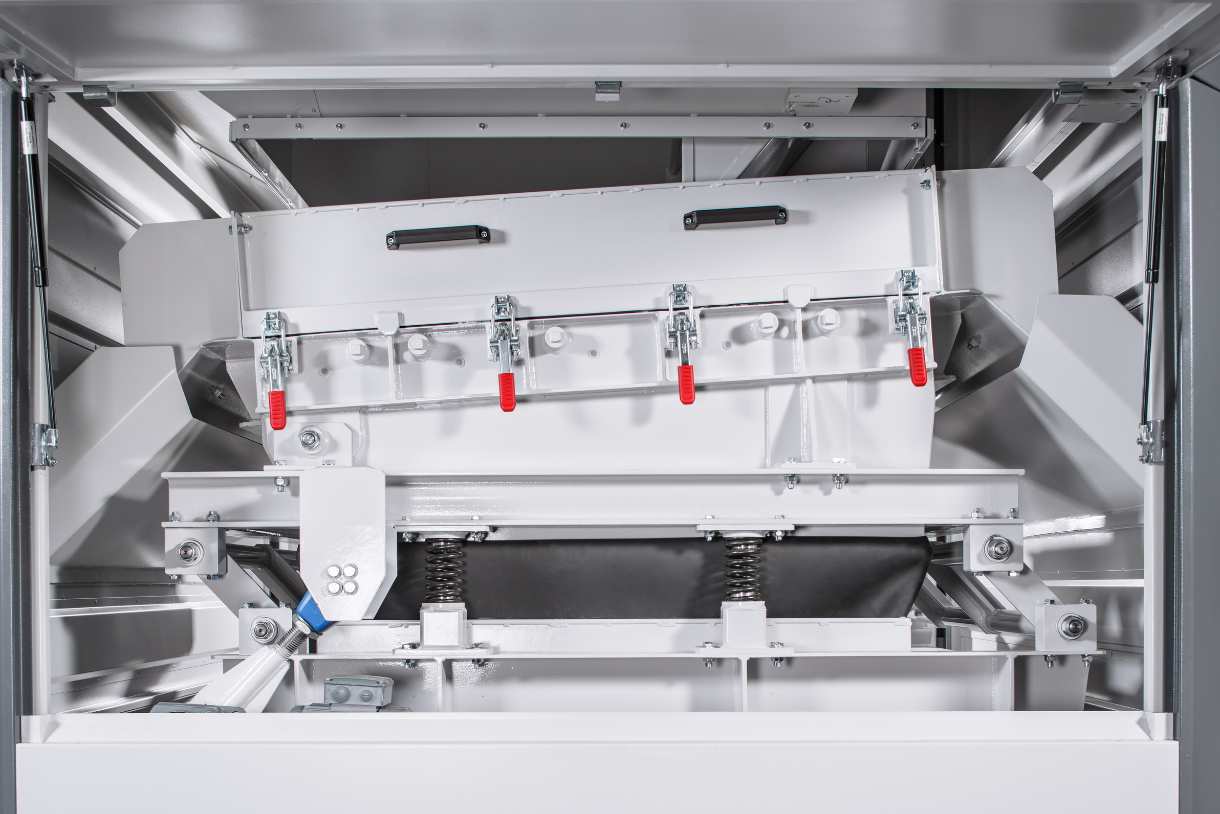

- A redesigned safety concept with a new cover significantly improves safety and meets the latest technical standards.

- Sorting parameters can be individually adjusted. The overall height of the machine has been reduced to optimise the footprint and it is capable of handling aggressive liquids.

- The new design minimises downtime and ensures stable performance.

- Intuitive operation, simple design and easy assembly, disassembly and transport are key features.

- Switching to this dry method not only saves water, but also significantly reduces energy consumption per tonne.

GSort & GSort GL

Applications

GSort GL:

The GSort GL series excels in processing compost MSW ranging from 0 to 10 mm and oversized compost MSW from 10 to 40 mm. It efficiently handles glass and organics within the 0 to 20 mm range, RDF from 0 to 40 mm, vermiculite, anthracite coal, PET-film, rubber and textile, and fine manganese ore. Its versatility makes it suitable for a broad spectrum of materials, ensuring operational efficiency across diverse recycling and waste management scenarios.

GSort:

The GSort series is designed for the precise separation of materials such as coal, magnesite, hematite, barite, celestite, attapulgite, manganese ore, and ferrum-manganese. It is also adept at recycling aluminum and processing crusted cables and crusted demolition waste. This series stands out for its ability to handle a wide range of densities and particle sizes, making it ideal for mining, recycling, and material recovery applications.

AGGRE-

GATES

BIOFUEL

CDW

MINING

META-

LLURGY

FOOD-

STUFF

ANIMAL

FEED

PLASTIC

GSORT & GSort GL

Advantages

The GSort model offers improved adaptability to changing inlet properties and processing of materials due to its multiple operating levers in the new design. It works well with highly abrasive mineral materials like manganese and provides exceptional purity compared to other market separation equipment.

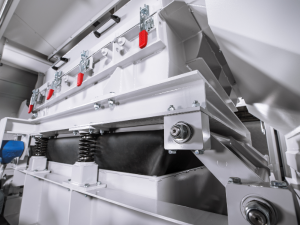

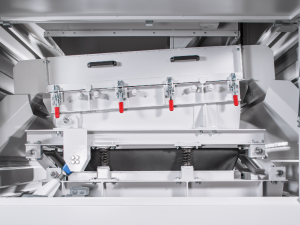

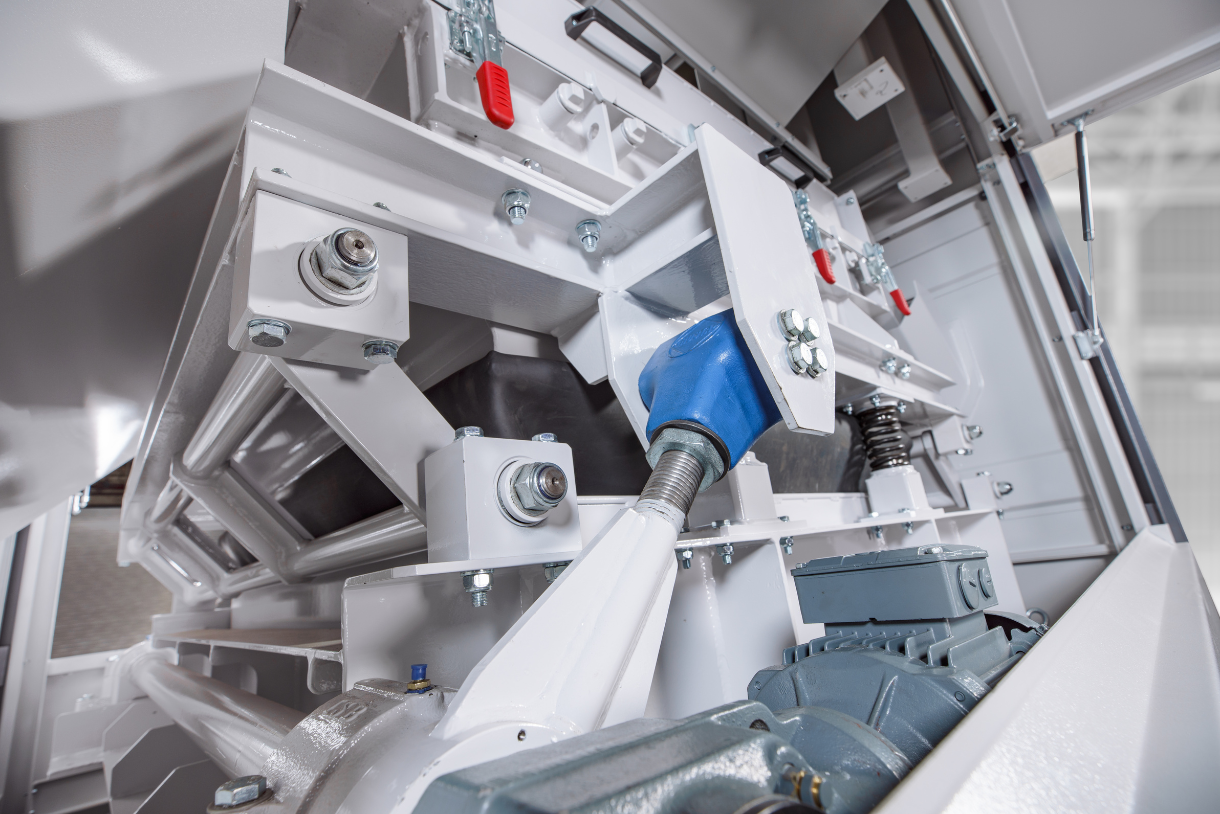

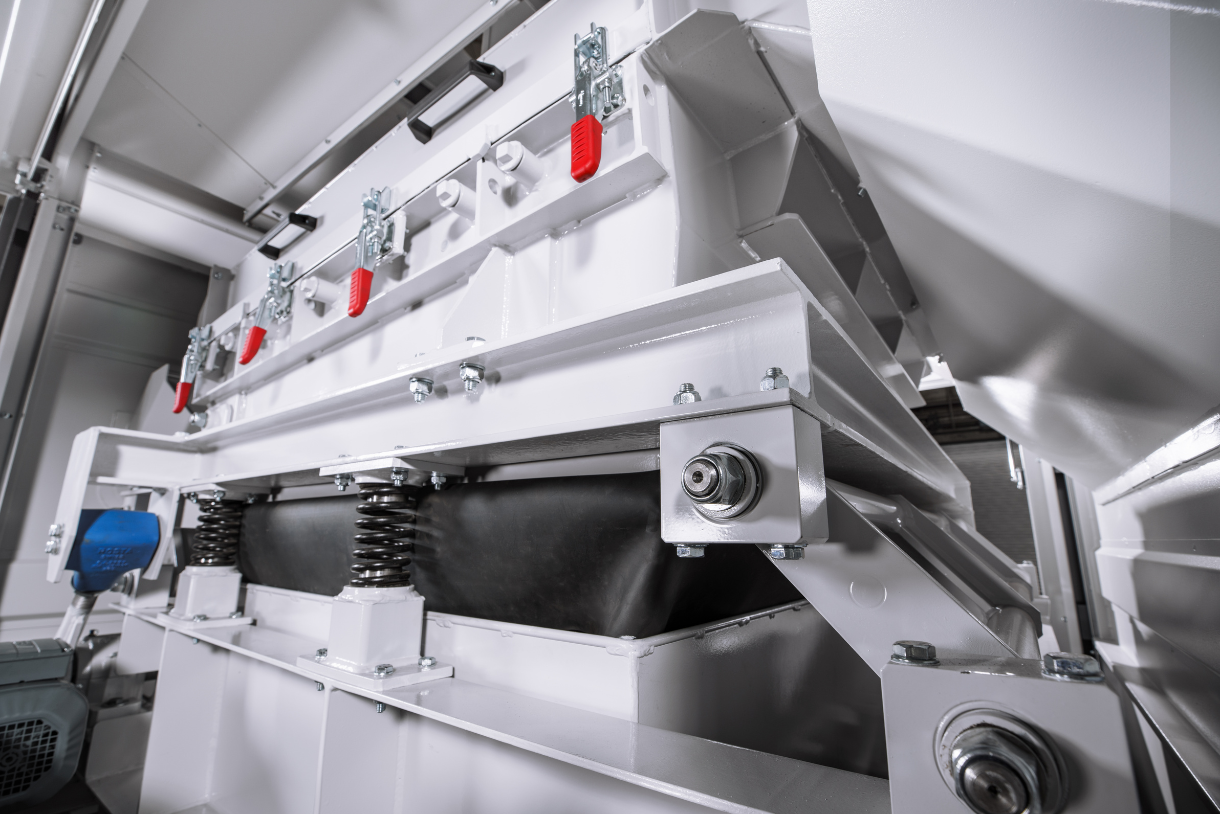

GSort is the leading solution for dry separation, featuring enhanced dimensioning for its vibratory mechanism, suspension frame, and wall. Additionally, it has a user-friendly mechanical maintenance design with side openings on the vibratory box.

Direct CAPEX: Capacity per unit of investment.

Installation costs vary based on two options: the standard height and a version with an integrated sunken heavy-duty base.

Direct maintenance costs kWh/t*

*Metric ton

Direct CAPEX: Capacity per unit of investment.

Installation costs vary based on two options: the standard height and a version with an integrated sunken heavy-duty base.

Direct maintenance costs kWh/t*

*Metric ton

Its design features unique improvements to the machine inlet, treatment deck design, and air distribution system.

The air distribution system provides greater flexibility as it's easily adjustable, reducing maintenance time associated with conventional methods.

GSort and GSort GL efficiently handle materials with moisture, provided there is no stickiness between particles and they can flow freely.

GSort

Photo Gallery

CONTACT FORM

Contact us!

Get in touch with us easily and directly using the attached form. We will get back to you as soon as possible!

Information on data protection can be found here.